Volumetric Flow Meters

by Alan Burgess | Apr 29, 2021 | General, Tech Tips | 0 comments

Get to know your Flow Meter

Volumetric flow meters are a common type of flow meter used to measure the flow of gases and liquids. Most common are variable area flowmeters as the tubes are tapered and increase in area in the vertical direction of the tube. As the fluid flow in the tube increases, the float will rise until there is a balance between the gravitational force and the drag force on the float. For gases, buoyancy forces are negligible. Since the tube is tapered, this provides a proportionate measure of the flow rate. However, there is a caveat; to obtain the actual flow rate, a correction must be made for gas type, pressure and temperature. In fact, volumetric flow meters measure the space taken up by the gas molecules and since gases are compressible, this correction for gas pressure and temperature must be made.

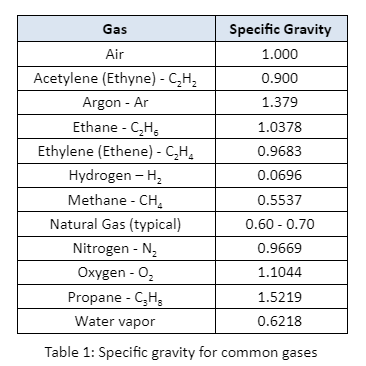

Flow meters are supplied with a factory calibration and this calibration specifies for full scale reading (100%) under these conditions:

- Fluid type

- Pressure

- Temperature

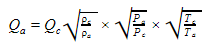

The correction for gas type, temperature and pressure is as follows:

Actual flow conditions:

Qa = Actual flow rate at 100% full scale

ρa = Specific gravity of gas being used

Pa = Actual absolute pressure in metering tube (bar or psi)

Ta = Actual absolute temperature (Kelvin)

Flowmeter design (calibration) conditions:

Qc = measured 100% flow rate under calibration conditions

ρc = Specific gravity of calibration gas

Pc = Absolute calibration pressure (bar or psi) (Pc = Pgauge + 14.7 psi (1.013 bar))

Tc = Absolute calibration temperature (Kelvin) (Tc = 20°C = 293.15 K)

It should be noted, the absolute temperature and pressure must be used. For absolute temperature use Kelvin (T[K] = T[°C] + 273.15) and for absolute pressure 14.7 psi must be added to the gauge pressure to obtain absolute pressure.

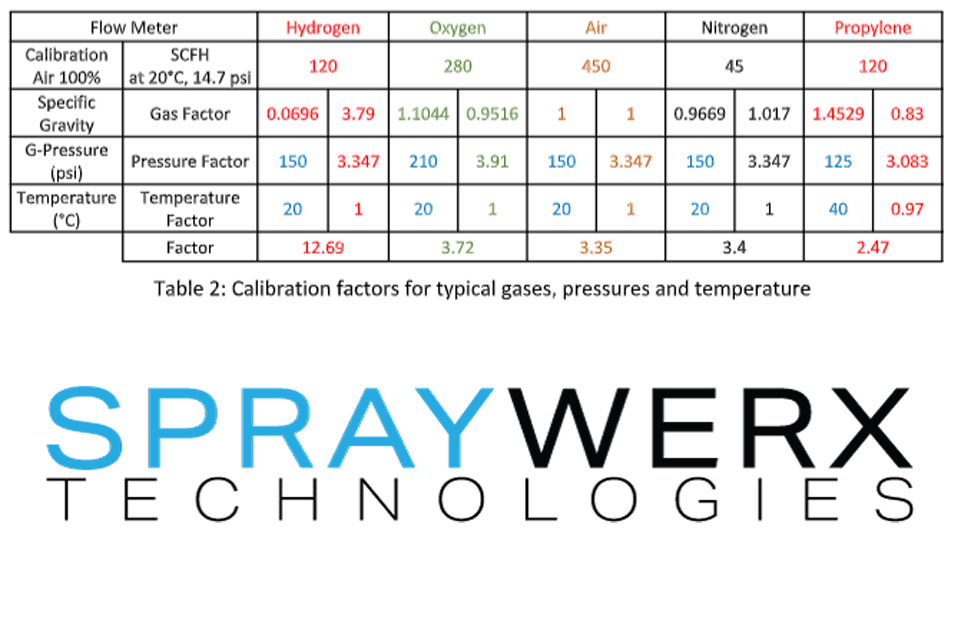

Calibration gas can vary, but the use of air is common as a calibration gas. To make to correction, the specific gravity of the gas needs to be known. The specific gravity is the ratio of molecular weight of the gas versus air. The molecular weight of air approximately 78% nitrogen, 21% oxygen and 1% argon is 28.96 g/mol. Table 1 provides specific gravities used in thermal spray.

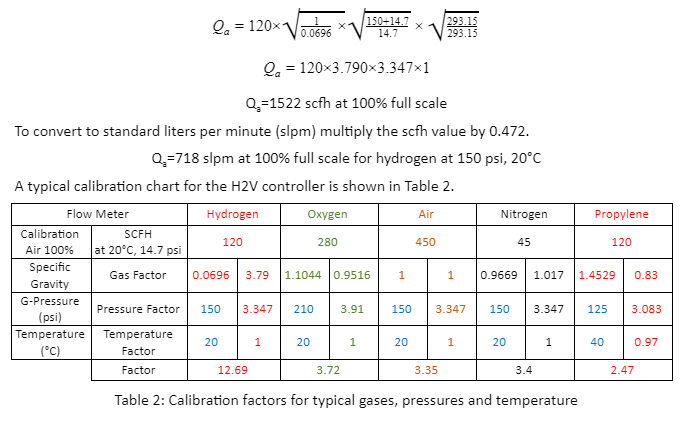

For example, a flow meter was calibrated with air at 20°C and 0 psi(g) and had a 100% scale measurement of 120 scfh. If the flow meter is used with hydrogen at 150 psi and 20°C, the calculation is as follows to calibrate for 100% full scale under these conditions:

Recent Posts

Demo coating and bond strength evaluation for Spraywerx Inc. on ID-Cyinder

ID-Nova vs Mini-Nova: Size Comparison

by Alan Burgess | May 29, 2021 | General, Id-Nova | 0 Comments

Stainless Steel – NbC Coating Produced with High Speed laser Cladding

by Alan Burgess | April 29, 2021 | General, Laser Cladding | 0 Comments