Providing Technology To Enable Technology

Learn more about our state-of-the-art products for your surface engineering solutions.

Industrially Proven Technology

Spraywerx delivers industrially proven, state-of-the-art thermal spray systems, equipment, and technology to organizations around the world. Spraywerx’s equipment is designed to meet a range of customer needs. Spraywerx products range from simple controllers and spray guns to sophisticated turn-key solutions.

Along with Spraywerx’ patent-pending ID-Nova HVOF technology, Spraywerx represents a full line of thermal spray and laser cladding products from GTV Germany.

Thermal Spray and its uses

Our Products

State-of-the-Art, industrially proven equipment and materials including: ID-HVOF, thermal spray, HVOF, laser cladding, powder feeders, spare parts and powders .

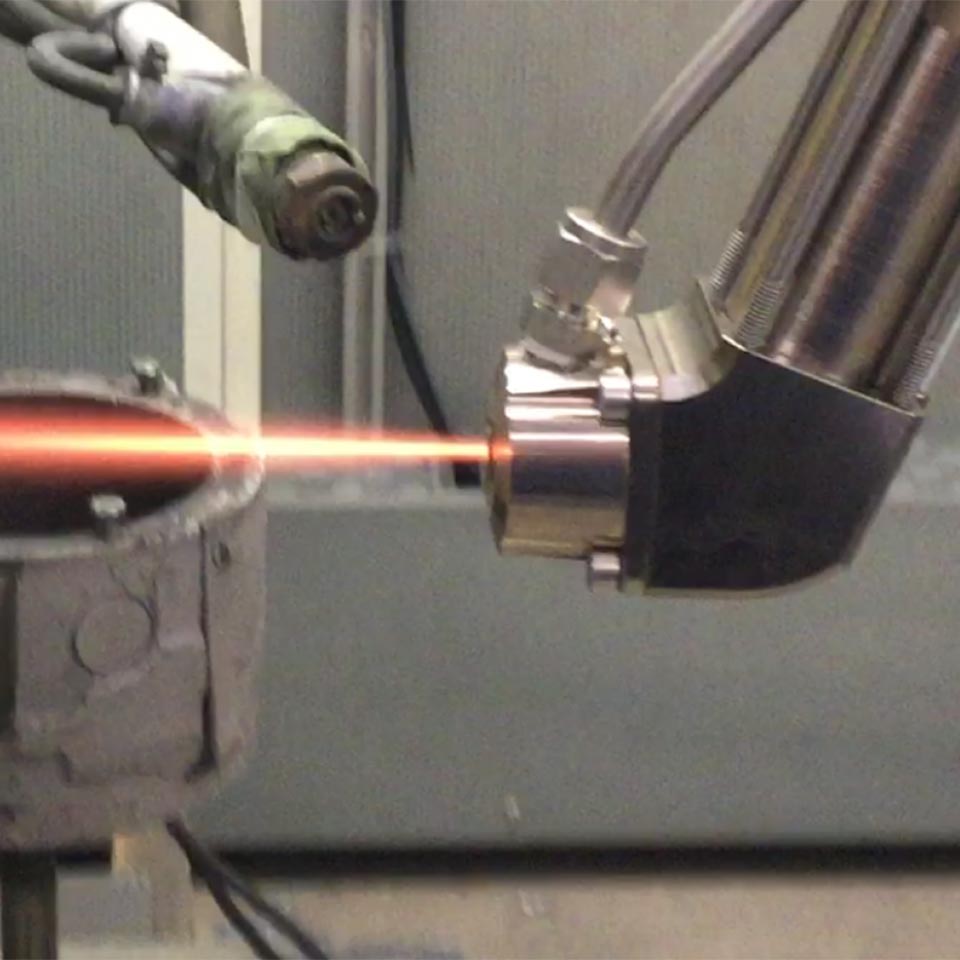

ID-NOVA HVOF

Small but packing a powerful punch, Spraywerx’s ID-Nova and Mini-Nova bring versatility for a variety of wear and corrosion resistant coatings. Learn more about this revolutionary new technology!

Thermal Spray

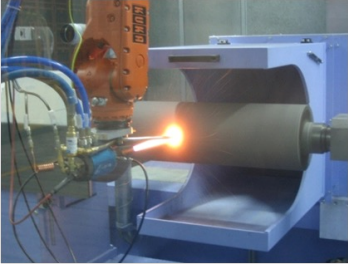

In addition to ID-HVOF, Spraywerx offers the full line of thermal spray systems and equipment from GTV including K2 HVOF, Plasma Spray, Powder Flame Spray, Wire Flame Spray and Wire Arc.

Laser Cladding

Laser systems ranging from 2 kW to 22 kW are available for a variety of industrial applications including high-speed laser cladding. Produced by GTV these industrial laser cladding systems are customized for turnkey production applications.

Powder Feeders

Spraywerx provides a range of powder feeders for thermal spray and laser cladding applications. The versatile GTV powder feeder is a work horse for industrial applications where consistency and reliability of powder feed is critical .

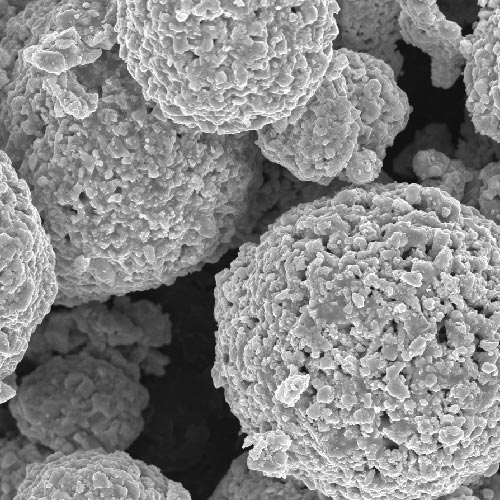

Powders

Spraywerx provides powders for thermal spray and laser cladding applications including a custom powder line for ID-HVOF. ID-HVOF powders are used for wear and corrosion prevention in industrial applications.

Fill out this form to learn more

Fill out this form to learn more

Fill out this form to learn more

Fill out this form to learn more

About Us

Spraywerx has developed patent-pending ID-HVOF technology. The ID-Nova and Mini-Nova HVOF spray torches are currently being used to produce industrial wear and corrosion-resistant coatings onto internal surfaces. Located in North Vancouver, BC, Canada, Spraywerx provides a variety of systems and equipment ranging from thermal spray, HVOF, laser cladding, powder feeders, and much more. Learn more about our process below or reach to our team and we’ll be happy to help answer any questions you may have!

How It Werx

For those new to themal spray, here are some of the basics:

Surface Preparation

Before spraying the coating, the surface must be cleaned and roughened. A fine grit blast roughens the surface to anchor the coating to the substrate. Bond strengths for carbide materials exceed 70 MPa or 10,000 psi.

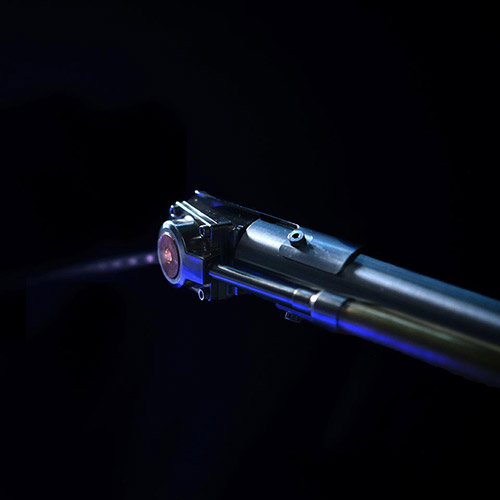

Generation of the Energetic Gas Flow

Thermal Spray uses hot gas to heat and accelerate the feedstock material. The hot gas is generated by combustion as in HVOF and flame spray or is created by striking arc between electrodes as in plasma and wire arc spraying.

Feedstock (powder, wire or suspension)

Powder and wire feeds stocks are the most common materials used in thermal spray. Suspension feeds are seeing interest for thermal barrier and catalytic coating applications.

Gas/Particle Interaction

In HVOF, powders are heated and accelerated to velocities exceeding 700 m/sec and bringing the feedstock materials to their melting point. All this is done in less than 1 ms.

Coating Formation

Molten or semi-molten particles impact the roughened substrate at high speed and “splat” on the surface. These pancake type splats are successively built up one upon the other creating the coating. Coatings are primarily evaluated by their hardness, porosity and stress state.

Post Processing of the Coating

Many applications require post machining or grinding of the coating after spraying. Coatings can be honed or superfinished to mirror-like finishes.

Still Have Questions?

We would be pleased to assist you with any question you may have. If we can’t provide you with a solution, we will try point you to someone who can.